New Drops!

We have been working hard to bring you items that you would love to have. Hit view all to see all the New Drops!

-

Wander Originals - Dad hat

Vendor:Wander OriginalsRegular price $25.00Regular priceUnit price / per -

Langford Industries - Snapback Hat

Vendor:Langford IndustriesRegular price $30.00Regular priceUnit price / per -

Defiance Kustoms Flame - Snapback Hat

Vendor:Defiance KustomsRegular price $30.00Regular priceUnit price / per -

Service and Build Log

Vendor:Defiance KustomsRegular price $17.00Regular priceUnit price / per -

Field Notes - Wander Originals

Vendor:Wander OriginalsRegular price $17.00Regular priceUnit price / per -

Field Notes - Wander Originals

Vendor:Wander OriginalsRegular price $17.00Regular priceUnit price / per -

Wander More Sherpa blanket - Mountains 4

Vendor:Wander OriginalsRegular price From $42.00Regular priceUnit price / per -

Full Windsor - Magware - Single Set - Green

Vendor:Full WindsorRegular price $34.99Regular priceUnit price / per -

Full Windsor - Magware - Single Set - Turquoise

Vendor:Full WindsorRegular price $34.99Regular priceUnit price / per -

Full Windsor - Magware - Single Set - Blue

Vendor:Full WindsorRegular price $34.99Regular priceUnit price / per

1

/

of

10

-

Wander Originals - Dad hat

Vendor:Wander OriginalsRegular price $25.00Regular priceUnit price / per -

Field Notes - Wander Originals

Vendor:Wander OriginalsRegular price $17.00Regular priceUnit price / per -

Field Notes - Wander Originals

Vendor:Wander OriginalsRegular price $17.00Regular priceUnit price / per -

Wander More Sherpa blanket - Mountains 4

Vendor:Wander OriginalsRegular price From $42.00Regular priceUnit price / per -

October Camping Skull T-Shirt

Vendor:Wander OriginalsRegular price From $25.00Regular priceUnit price / per -

Lounging Sweatshirt

Vendor:Wander OriginalsRegular price From $45.00Regular priceUnit price / per -

Wandering Sweatshirt

Vendor:Wander OriginalsRegular price From $45.00Regular priceUnit price / per -

Hiking Sweatshirt

Vendor:Wander OriginalsRegular price From $45.00Regular priceUnit price / per -

Camping Sweatshirt

Vendor:Wander OriginalsRegular price From $45.00Regular priceUnit price / per -

Campfire Sweatshirt

Vendor:Wander OriginalsRegular price From $45.00Regular priceUnit price / per

1

/

of

10

-

Wheelin' Sweatshirt

Vendor:Defiance KustomsRegular price From $45.00Regular priceUnit price / per -

Wheelin' Shirt

Vendor:Defiance KustomsRegular price $25.00Regular priceUnit price / per -

SXS Super Jump T-Shirt

Vendor:Defiance KustomsRegular price From $25.00Regular priceUnit price / per -

Overlanding Sweatshirt

Vendor:Defiance KustomsRegular price From $45.00Regular priceUnit price / per -

Overlanding Shirt

Vendor:Defiance KustomsRegular price From $25.00Regular priceUnit price / per -

Off-Roading Sweatshirt

Vendor:Defiance KustomsRegular price From $45.00Regular priceUnit price / per -

Off-Roading Shirt

Vendor:Defiance KustomsRegular price From $25.00Regular priceUnit price / per -

Cruising Sweatshirt

Vendor:Defiance KustomsRegular price From $45.00Regular priceUnit price / per -

Cruising Shirt

Vendor:Defiance KustomsRegular price $25.00Regular priceUnit price / per -

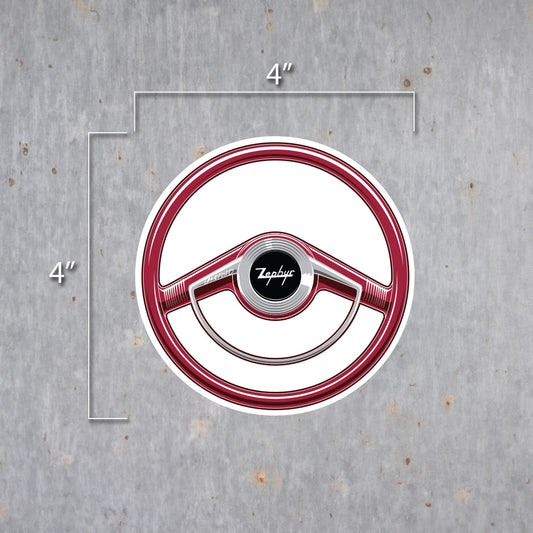

Zephyr Steering Wheel Vinyl Sticker

Vendor:Defiance KustomsRegular price $4.00Regular priceUnit price / per

1

/

of

10